GRC spray machine is used for applying Glassfiber Reinforced Concrete (GRC) in construction and architectural applications. This machine efficiently sprays a mixture of cement, sand, water, and chopped fiberglass strands to create lightweight, durable, and high-strength GRC components.

Specifications of Grc Glass Fiber Spraying Machine

| Model | YG-Y80 GRC shotcrete machine (screw type) | YG-Y100 GRC Spray machine (plunger type) |

| Power supply | 380V 50HZ (three-phase) | 380V 50HZ (three-phase) |

| Production efficiency | 300-400㎡/h | 300-600㎡/h |

| Working air pressure | 0.6-0.8mpa | 0.6-0.8mpa |

| Capacity | 50L | 60L |

| Conveying capacity | 300-1600kg/h | 300-1600kg/h |

| Working area | 4.0 meters (horizontal arm radius) | 4.5 meters (horizontal arm radius) |

| Speed | 40-200r/min | 20-280r/min |

| Power | 2.2-3.0KW stepless speed regulating motor | 1.5-2.2KW stepless speed regulating motor |

| Dimension | 1400*1000*2200mm | 1300*1000*2200mm |

| Equipment weight | 220kg | 300kg |

Common Uses of a GRC Spray Machine

- Architectural Cladding & Facades – Producing decorative and functional exterior wall panels.

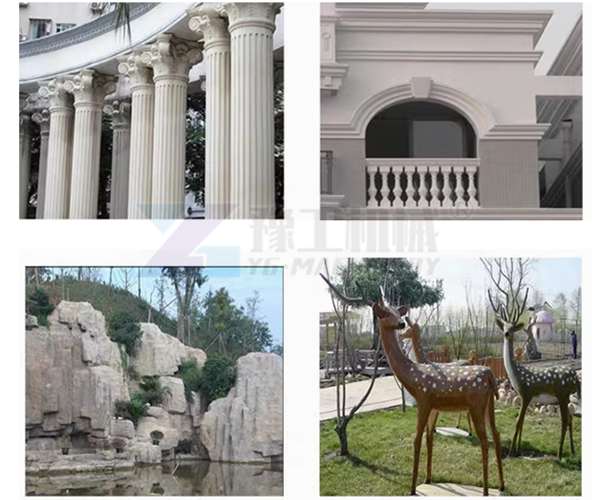

- Ornamental Features – Creating intricate columns, balustrades, cornices, and moldings.

- Precast GRC Panels – Manufacturing lightweight yet strong panels for construction.

- Landscaping Elements – Making planters, garden ornaments, fountains, and sculptures.

- Infrastructure Components – Used for manufacturing bridge panels, sound barriers, and lightweight tunnel linings.

- Theme Parks & Movie Sets – Crafting realistic and durable decorative structures.

Y80 GRC Shotcrete Machine Screw Type Features

- This GRC spraying machine adopts an inclined screw pump, composed of a duplex high-wear-resistant stainless steel rotor and a PTFE rubber stator. It ensures even material feeding with no significant pulsation, maintaining a uniform mix ratio for machine-sprayed GRC products. The design is reasonable, with a compact structure, small size, and easy disassembly and maintenance.

- It uses stepless speed control technology to adjust the flow rate, achieving an optimal spraying effect.

- The machine covers a large working area, with the horizontal swing arm of the spray gun and feed pipe reaching up to 10 meters in diameter. With an extended hose, it can operate within 120 square meters without moving the platform.

- High efficiency and excellent quality—compact in size, easy to transport on-site, with affordable and readily available spare parts, ensuring low operating costs.

What Can a GRC Spray Machine Produce?

The GRC glass fiber spraying machine is compatible with various spraying materials, including mortar (GRC mix with chopped fiberglass), gypsum, magnesium oxide cement, textured coatings, waterproofing materials, and applications such as small villas, clubhouses, bridges, artificial rock formations, dams, and river embankment guardrails.

The GRC spraying machine can produce a wide range of GRC products, including GRC moldings, column heads, column bases, column piers, smooth columns, reliefs, flower pots, railings, window and door frames, fountains, panels, and garden sculptures.

Buy your GRC Spryaing Machine Today

If you’re looking for a high-efficiency GRC fiberglass spraying machine to boost your production and achieve superior-quality results, we’ve got you covered! Contact us today for pricing, specifications, and expert guidance tailored to your needs.

📩 Leave your inquiry now—our team is ready to assist you! 🚀