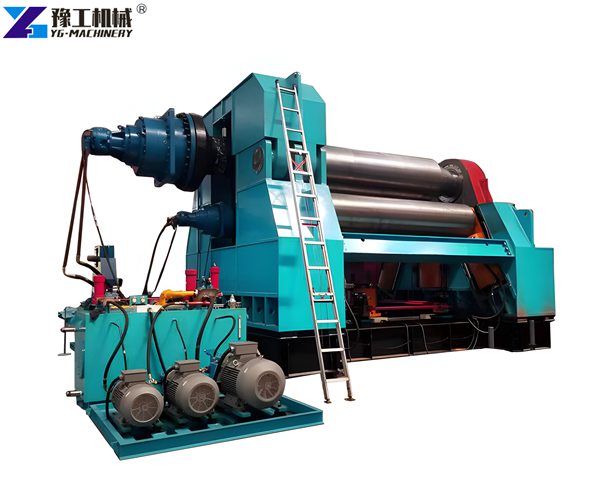

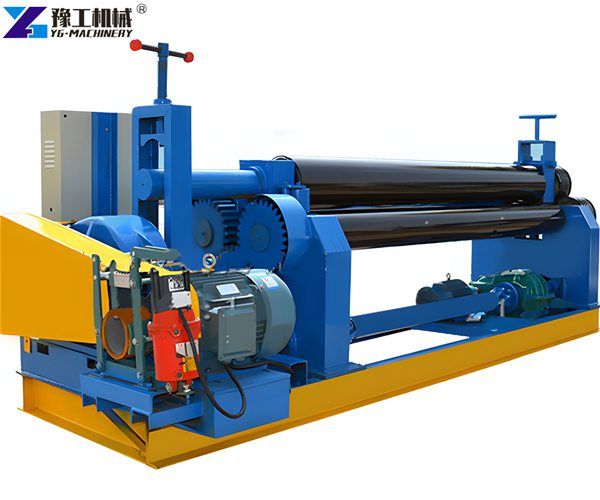

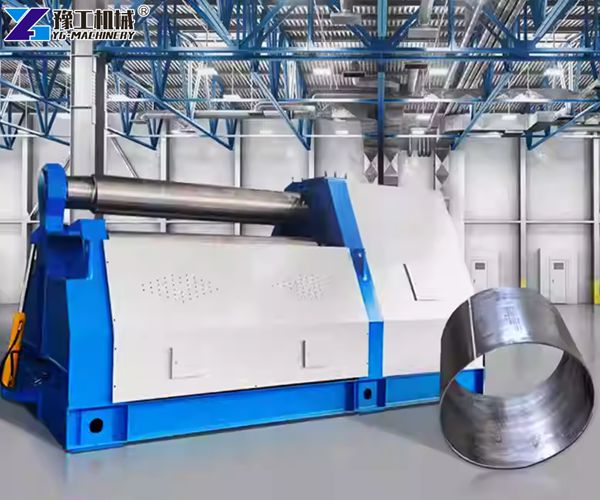

YG steel plate rolling machine is a mechanical powerhouse designed to bend and curve metal sheets into cylinders, cones, or other rounded shapes. It’s a must-have for industries dealing with shipbuilding, aerospace, automotive, and metal fabrication. These machines come in different configurations—two-roll, three-roll, and four-roll models—each with its own advantages.

Buy YG Steel Plate Bending Machine

| Model | Working Length (mm) | Max. Thickness (mm) | Pre- Bending (mm) | Upper (Φmm) | Under (Φmm) | Side (Φmm) | Motor Power (km) | dimension(cm) |

| W12S-4×2000 | 2000 | 4 | 3 | 160 | 140 | 120 | 2.2 | 392x86x114 |

| W12S-4×2500 | 2500 | 4 | 3 | 190 | 170 | 150 | 3 | 402x125x138 |

| W12S-4×3200 | 3200 | 4 | 3 | 210 | 190 | 170 | 7.5 | 466x132x137 |

| W12S-4×4000 | 4000 | 4 | 3 | 270 | 250 | 210 | 5.5 | 600x143x152 |

| W12S-6×2000 | 2000 | 6 | 4 | 190 | 170 | 150 | 3 | 402x125x138 |

| W12S-6×2500 | 2500 | 6 | 4 | 210 | 190 | 170 | 7.5 | 466x132x137 |

| W12S-8×2000 | 2000 | 8 | 6 | 210 | 190 | 170 | 7.5 | 416x132x137 |

Whether you’re fabricating pressure vessels, creating metal pipes, or shaping structural components, this machine is the backbone of heavy-duty metalworking.

How Does a Steel Plate Rolling Machine Work?

At its core, a steel plate rolling machine works by applying force through rollers to bend metal sheets into desired shapes. Here’s how:

- Material is placed between rollers.

- Rollers apply pressure, gradually bending the plate.

- Repeated passes refine the curvature.

- The final shape—cylindrical, conical, or otherwise—is achieved.

Our CNC automatic metal plate roller allows automated precision and repeatability in mass production.

Types of Steel Plate Rolling Machines

| Type | Features | Best For |

|---|---|---|

| 2-Roll Machines | Simplest design, fast operation | Light-gauge metals, thin sheets |

| 3-Roll Machines | Most common, offers good control | Medium to heavy-duty fabrication |

| 4-Roll Machines | High precision, CNC automation available | Thick steel plates, industrial applications |

Each type serves a different purpose, so selecting the right one depends on your industry needs and budget.

Why Invest in a Steel Plate Rolling Machine?

Here’s why businesses in construction, manufacturing, and shipbuilding can’t get enough of these machines:

✅ Cost Efficiency – Reduce outsourcing costs by fabricating in-house.

✅ Precision & Quality – Achieve consistent and accurate metal bending.

✅ Versatility – Works on steel, aluminum, and other alloys.

✅ Scalability – From small jobs to large industrial projects, there’s a machine for every need.

Frequently Asked Questions (FAQs)

1. What industries use steel plate rolling machines?

Industries like oil & gas, aerospace, automotive, and shipbuilding rely on them to shape metal for tanks, pipes, pressure vessels, and structural components.

2. How thick of a plate can a rolling machine handle?

It depends on the model. Some machines handle thin sheets (1mm), while industrial models can roll plates over 100mm thick.

3. Are CNC-controlled plate rolling machines worth it?

Yes! If you need high precision, repeatability, and minimal human error, CNC models are the way to go. They’re especially useful for complex and high-volume projects.

4. What should I consider when buying a steel plate bending machine?

- Material thickness & width capabilities

- Manual vs. CNC control

- Number of rolls (2, 3, or 4)

- Brand reputation and after-sales support

Conclusion: Is It the Right Machine for You?

If your business involves shaping metal sheets into curved forms, a steel plate rolling machine is a game-changer. Whether you need basic manual rollers or high-tech CNC models, there’s a perfect fit for your needs. Ready to take your metal fabrication to the next level?

Explore our collection of steel plate rolling machines today!