When it comes to cutting through concrete, traditional saws often struggle with efficiency, precision, and durability. Enter the diamond wire saw—a cutting-edge tool designed to handle the toughest concrete-cutting jobs with speed and precision. Whether you’re working on large-scale demolition, bridge reconstruction, or precise architectural modifications, a diamond wire saw for concrete is the ultimate solution.

In this article, we’ll explore everything you need to know about diamond wire saws, including their benefits, working mechanism, applications, and key factors to consider before purchasing one.

What Is a Diamond Wire Saw for concrete?

The diamond wire saw is a cutting tool that utilizes a wire embedded with industrial-grade diamonds to cut through hard materials such as concrete, reinforced concrete, stone, and metal. The diamond wire, looped around the material, moves continuously in a high-speed motion, ensuring clean and precise cuts with minimal vibration.

Technical Parameters of concrete wire saw for sale

| Hydraulic Pump | YG-25 | Motor Power | 25kw |

| Voltage | 220V/380V, 50Hz | Motor Type | HM-80, 2 Cylinders |

| Rotation | 1300r/min | Working Pressure | 15-20Mpa |

| Weight | 170kg | Size | 720*650*1050mm |

| Frame & Wheels | Aluminum | Wheels | 10 |

| Weight | 75kg | Size | 90*90*1700mm |

| Diamond Wire Saw | Diamond Wire | Specification | φ11.5mm 40beads/m |

| Cutting speed | 3~5m2/h | Wire life | 2~3m2/m |

How Does a Diamond Wire Saw Work?

- Wire Installation: The diamond wire cutting machine is looped around the material that needs to be cut.

- Pulley System: The wire is guided by a series of pulleys connected to a drive system.

- High-Speed Rotation: The wire moves rapidly, driven by a motor, while water is sprayed to cool the wire and minimize dust.

- Efficient Cutting: As the wire moves through the material, the embedded diamonds grind through the concrete with minimal effort.

Applications of Diamond Wire Saws

- Bridge and Dam Demolition – Ideal for cutting reinforced concrete structures in large-scale demolitions.

- Building Renovations – Used for creating openings in walls, slabs, and beams.

- Underwater Cutting – Essential for cutting submerged structures without requiring divers.

- Road and Highway Construction – Helps in precise removal of concrete slabs and columns.

- Industrial and Nuclear Facilities – Used for decommissioning and cutting through heavily reinforced concrete.

Frequently Asked Questions (FAQs)

1. How long does a diamond wire last?

The lifespan depends on the material being cut and the quality of the diamond wire saw for concrete. Typically, a high-quality wire can last 20–100 square meters of cutting before needing replacement.

2. Can a diamond wire saw cut through steel-reinforced concrete?

Yes! Diamond wire saws are specifically designed to cut through heavily reinforced concrete, including rebar and embedded steel structures.

3. Is a diamond wire saw better than a traditional concrete saw?

For precision, speed, and minimal structural impact, a diamond wire saw for concrete is superior to traditional saws, especially in large-scale or sensitive projects.

4. Where can I buy a diamond wire saw for concrete cutting?

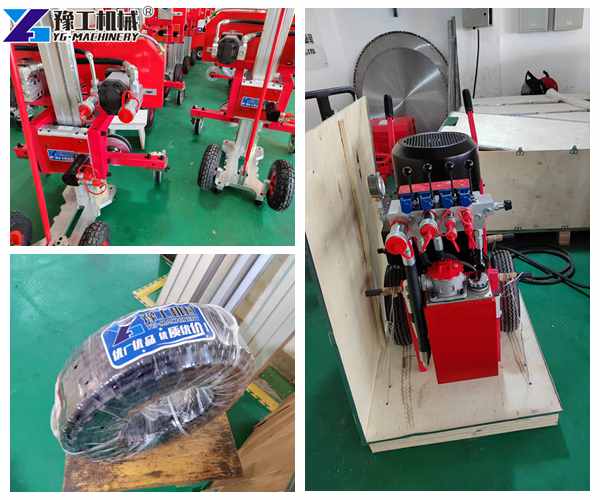

You can purchase diamond wire saws from construction equipment supplier – YG Machinery. We offer customized solutions.

Conclusion

A diamond wire saw for concrete is an indispensable tool for construction professionals, offering precision, speed, and versatility in cutting through even the toughest materials. Whether you’re tackling demolition, renovation, or specialized construction work, investing in the right diamond wire saw can significantly enhance efficiency and project success.

Looking for the best diamond wire saw for sale? Contact us today to explore top-quality options that meet your project requirements.