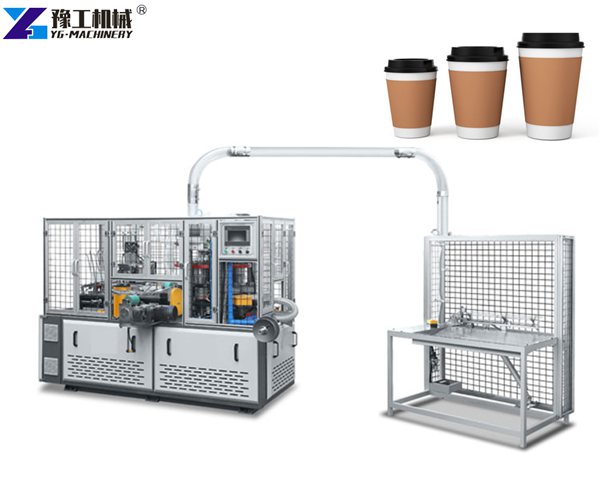

Are you looking for a high-performance, cost-effective paper cup forming machine? YG Machinery is your go-to solution. Boost your production efficiency, reduce costs, and meet growing market demands with our top-of-the-line paper cup machines. Contact us to get the paper glass machine price.

Technical Parameters of Paper Cup Forming Machine

| Model | YG- M100 | YG-M22S |

| Cup size | 2-9oz | 6oz-22oz |

| Raw material | Singe PE or Double PE coated paper | Single and double PE coating paper |

| Paper thickness | 150-260 gsm | 160-300gsm |

| Top mouth diameter | 40-76mm | 60mm-90mm |

| Bottom diameter | 28-54mm | 40mm-70mm |

| Bottom depth | 5mm-10mm | 5mm-10mm |

| Height | 30-100mm | 60mm-180mm |

| Capacity | 90-110 cups per minute | 60-90 cups per minute |

| Power | 4.5 kw | 16kw |

| Air consumption | 0.4m³/min, 0.4-0.6Mpa | 0.4m³/min, 0.5-0.8Mpa |

| Weight | 1500kg | 2200kg |

| Dimension | 1900x875x1550mm 900x600x1500mm | 1900x1350x2000mm 1220x950x2080mm |

Features of Paper Glass Machine

- Hot air or ultrasonic sealing ensures leak-proof bases.

- Uses high-efficiency heaters or ultrasonic systems to seal the cup wall.

- Touchscreen or PLC interface for easy operation and monitoring.

- Automatically collects waste paper and trims for easy disposal.

- It can produce various cup/glass sizes, often from 50 ml up to 650 ml or more.

FAQs About YG Paper Cup Forming Machines

How much does a YG paper cup forming machine cost?

Prices vary depending on model, automation level, and production speed. Contact YG Machinery for a detailed quote.

Can the machine produce both hot and cold beverage cups?

Yes! The machine supports single and double PE-coated paper, making it suitable for both hot and cold drinks.

What is the lifespan of a paper cup machine?

With proper maintenance, YG machines can last 8-10 years or more.

How do I maintain my paper cup forming machine?

Regular lubrication, timely replacement of worn-out parts, and keeping the machine clean ensure optimal performance.